Reliable Electrical Solutions for the Food & Beverage Industry

At Bharat Trading Company (BTC), we understand the special demands of food and beverage manufacturing environments, where safety, hygiene, and uninterrupted operations are the key. That’s why we supply high-quality electrical cables, control wiring, accessories, and cable management systems that are specially built to perform reliably in challenging production and packaging conditions.

Our solutions are designed to support your smooth, continuous operations while meeting industry standards related to cleanliness, durability, and performance. Our overall aim is to help manufacturers focus on efficiency, quality, and compliance with confidence.

What Is the Food & Beverage Industry and How Does BTC Support It?

The food and beverage industry is all about bringing safe, high‑quality products to people every day. It covers everything from processing raw ingredients to manufacturing, packaging, and distributing food and drinks. This is all done under strict hygiene and safety standards. Because even the smallest disruption can affect production, this industry relies on systems that are reliable, efficient, and built to last. That’s where Bharat Trading Company (BTC) comes in. And, we proudly support this industry by supplying best-in-class electrical solutions that help to keep these plants run safely and smoothly. Our range includes durable power cables, precise control and instrumentation wiring, and accessories designed to handle heat, moisture, and demanding environments. From lugs and glands to heat‑shrink insulation and organised cable management solutions, we ensure that your operations stay safe, compliant, and continuously powered. With BTC, you don’t just get products, you get peace of mind knowing your plant is supported by electrical solutions built for performance and reliability.

What Is the Food & Beverage Industry and How Does BTC Support It?

The food and beverage industry is all about bringing safe, high‑quality products to people every day. It covers everything from processing raw ingredients to manufacturing, packaging, and distributing food and drinks. This is all done under strict hygiene and safety standards. Because even the smallest disruption can affect production, this industry relies on systems that are reliable, efficient, and built to last. That’s where Bharat Trading Company (BTC) comes in. And, we proudly support this industry by supplying best-in-class electrical solutions that help to keep these plants run safely and smoothly. Our range includes durable power cables, precise control and instrumentation wiring, and accessories designed to handle heat, moisture, and demanding environments. From lugs and glands to heat‑shrink insulation and organised cable management solutions, we ensure that your operations stay safe, compliant, and continuously powered. With BTC, you don’t just get products, you get peace of mind knowing your plant is supported by electrical solutions built for performance and reliability.

Overview of Electrical Requirements in Food & Beverage Processing Facilities

Food and beverage processing plants across India including cities like Pune, Mumbai, Nashik, Aurangabad, Bengaluru, and Hyderabad, run in environments where hygiene, safety, and nonstop production are non‑negotiable. Electrical systems in such plants need to perform reliably to meet strict regulatory standards while handling daily challenges like moisture, frequent washdowns, changing temperatures, and round‑the‑clock operations. To keep these plants running smoothly, electrical systems need to be tough, reliable, and built for long service life. That’s exactly what Bharat Trading Company (BTC) delivers. Bharat Trading Company (BTC) supplies electrical products that are specifically suited for these challenging conditions. Our solutions are designed to deliver consistent performance, long service life, and a high level of safety, helping food and beverage manufacturers maintain smooth operations and stay compliant with industry requirements.

Where BTC Products Are Used in Food & Beverage Facilities

Electrical systems play a vital role in every corner of a food and beverage plant. From preparation to packaging, BTC’s products are trusted to keep operations safe, reliable, and efficient. Here’s how they support different areas

Food Processing and Preparation Areas

Beverage Bottling and Filling Lines

Cold Storage and Refrigeration Units

Packaging and Dispatch Areas

Utility Systems and Support Infrastructure

Overview of Electrical Requirements in Food & Beverage Processing Facilities

Food and beverage processing plants across India including cities like Pune, Mumbai, Nashik, Aurangabad, Bengaluru, and Hyderabad, run in environments where hygiene, safety, and nonstop production are non‑negotiable.

Electrical systems in such plants need to perform reliably to meet strict regulatory standards while handling daily challenges like moisture, frequent washdowns, changing temperatures, and round‑the‑clock operations.

To keep these plants running smoothly, electrical systems need to be tough, reliable, and built for long service life. That’s exactly what Bharat Trading Company (BTC) delivers.

Bharat Trading Company (BTC) supplies electrical products that are specifically suited for these challenging conditions.

Our solutions are designed to deliver consistent performance, long service life, and a high level of safety, helping food and beverage manufacturers maintain smooth operations and stay compliant with industry requirements.

Product Categories Used in the Food & Beverage Industry

At Bharat Trading Company (BTC), we supply a complete range of electrical products designed for food‑grade environments. Each product and solution is built to handle the unique challenges of food and beverage facilities.

Control & Instrumentation Cables

Modern food and beverage plants rely on automation and precise control. BTC’s control and instrumentation cables ensure accurate and reliable signal transmission for sensors and control systems.

Explore products

Flexible Industrial Wires & Cables

Designed for machines and production areas that require constant movement, our flexible industrial cables adapt without damage or performance loss.

View cables

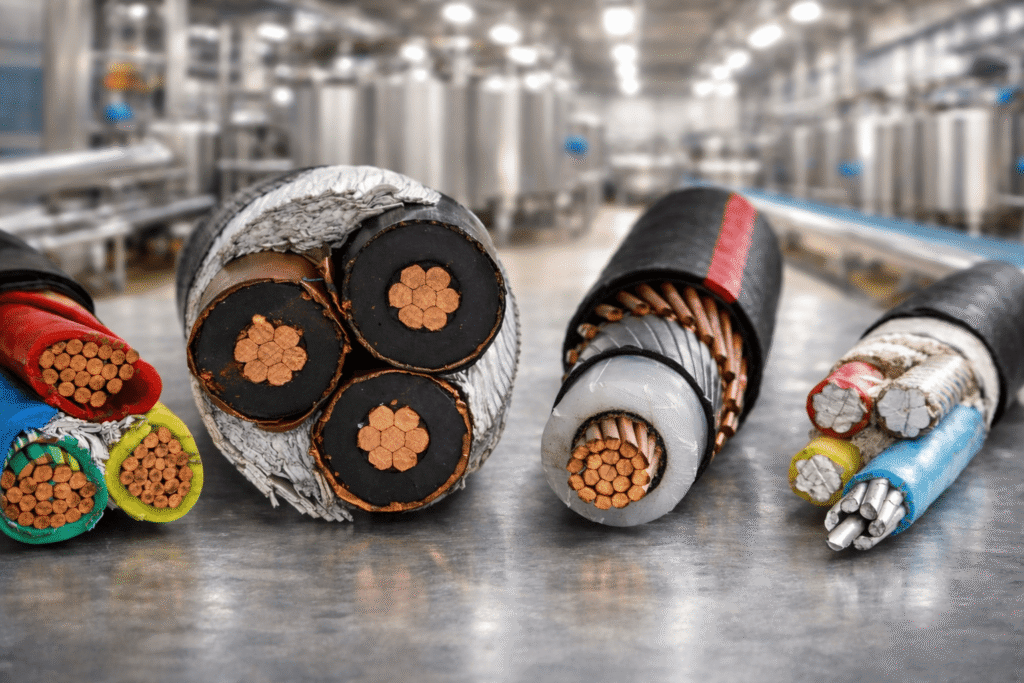

Armoured & Unarmoured Power Cables

BTC power cables deliver dependable electricity for indoor and outdoor installations, offering the right protection based on the application.

Check options

Cable Lugs & Glands (Moisture-Resistant)

Designed for washdown and wet environments, BTC’s cable lugs and glands protect connections from water, dust, and vibration.

Browse products

Heat Shrink Sleeves & Insulation Accessories

Heat shrink sleeves enhance electrical safety by insulating, protecting, and clearly identifying cables in food-grade environments.

View solutions

Cable Management Systems

Organised cabling improves hygiene, safety, and maintenance efficiency. BTC’s ducts, trays, and conduits keep wiring secure and accessible.

View systemsWhy Electrical Reliability Matters in the Food & Beverage Industry?

Why Electrical Reliability Matters in the Food & Beverage Industry?

In the food and beverage industry, reliability isn’t just about keeping the lights on and cooking, it’s about protecting products, people, and processes. Even a short electrical disruption can cause production delays, spoil batches, create safety risks, or lead to non‑compliance with strict regulations. Every part of a plant from mixers and ovens to chillers, conveyors, and packaging machines every element depends on stable power and precise control to run smoothly. When electrical systems fail, the impact is immediate and costly. That’s why high‑quality electrical components make all the difference. They help to prevent unplanned shutdowns, safeguard sensitive equipment, and support hygienic operations by ensuring all the installations are safe, organised, and built to last. By choosing BTC’s reliable solutions, food and beverage facilities industry owners can focus on smooth production and consistent output without unexpected interruptions.

Comparison: Electrical Options in Food & Beverage Applications

Choosing the right type of cable is especially important in food and beverage facilities, where safety, hygiene, and reliability are non‑negotiable. Here’s a quick comparison to help you see which options work best in different situations

| Application Area | Better Option | Why It Matters |

|---|---|---|

| Washdown & Moisture-Prone Zones | Moisture-Resistant Cables | Food and beverage plants go through frequent washdowns to maintain hygiene. Standard cables can fail when exposed to water. Moisture-resistant cables ensure durability and safety during frequent cleaning. Unlike standard cables, they don’t degrade quickly, making them a safer and longer-lasting choice for wet and washdown areas. |

| Moving Machinery & Equipment | Flexible Cables | Many machines in processing units move, vibrate, or operate continuously. Flexible cables bend easily without cracking or breaking. Unlike rigid wiring, they move with machinery, reducing wear, preventing breakdowns, and minimizing maintenance issues. |

| Enclosed Processing Areas | Fire-Retardant Cables | Fire-retardant cables slow the spread of fire and produce less smoke during overheating. Conventional PVC insulation may not offer sufficient protection. These cables add an extra layer of safety, protecting both workers and critical equipment in confined spaces. |

By matching the right cable to the right environment, food and beverage companies can reduce risks, improve efficiency, and keep operations running smoothly.

Types and Categories of Food & Beverage Electrical Systems

Food and beverage facilities rely on a wide range of electrical systems to keep operations running smoothly, safely, and efficiently. At Bharat Trading Company (BTC), we understand that each area of a plant has unique electrical needs. That’s why we offer the right cables, components, and accessories suited for every application.

- Processing Lines: The heart of any food facility is its processing line. These systems require reliable, durable cables that can handle constant operation, heat, and frequent cleaning. BTC’s electrical components deliver steady power to your mixers, grinders, ovens, and other equipment helping to maintain quality and speed in production.

- Packaging system electrical networks: Once products are ready, packaging systems take over. Our wiring and accessories ensure that packaging machines operate reliably, keeping output fast, accurate, and hygienic.

- Cold Storage Electrical Systems: Temperature control is critical in food and beverage operations. And, cold storage areas require special demands on electrical systems due to low temperatures and moisture. BTC supplies durable cables and protective accessories designed for cold storage environments, ensuring uninterrupted power to refrigeration units and helping maintain product freshness and quality.

- Utility and boiler electrical systems: Behind the scenes, utility and boiler systems keep plants running 24x7. Utilities such as boilers, compressors, and water treatment units operate in high-temperature and demanding conditions. BTC’s heat-resistant and heavy-duty electrical components are built to withstand these environments while supporting safe and efficient energy use.

- Automation and control networks: Today, modern food and beverage plants rely heavily on automation for improved efficiency and quality control. And, BTC supports these systems with control and instrumentation cables that enable smooth communication between PLCs, sensors, and machines, helping plants achieve better accuracy and process control. This results in smarter, faster, and more precise production.

- Safety and monitoring systems: Reliable electrical systems are essential for safety in food and beverage facilities. BTC’s cabling and accessories support alarms, emergency shut-offs, and monitoring systems. Overall, our goal is to ensure compliance and protect both workers and equipment.

Key Challenges Faced in Food & Beverage Electrical Systems

- Moisture, Steam, and Frequent Washdowns: Food processing areas are always exposed to water, steam, and cleaning chemicals due to routine washdowns and sanitation processes. If electrical components are not properly protected, this exposure can lead to corrosion, short circuits, and premature failures. In the end, this leads to a costly downtime.

- Temperature Extremes: Today many facilities operate across a wide range of temperatures. While bakeries, boilers, and cooking zones experience high heat, areas such as cold storage and freezers operate at very low temperatures. To survive in these conditions these electrical cables and accessories must be able to perform reliably in both conditions without cracking, melting, or losing efficiency.

- Continuous 24×7 Operations: With growing cloud kitchens and food deliveries, many food and beverages plants run continuously to meet the production and user demands. This means electrical systems are under constant load. Thus, all your cables, connectors, and accessories need to be durable and reliable enough to handle nonstop operation without overheating or breakdowns.

- Hygiene and Safety Compliance: Electrical installations in food plants must comply with strict food safety and workplace safety standards. Poorly managed wiring or accessories can pose risks not only to equipment but also to your team and overall environment.

- Automation and Process Control Complexity: Modern food plants rely heavily on automation for accuracy and efficiency. From conveyors and mixers to packaging lines every process is automated to minimize human errors. These systems require precise signal transmission and well‑organised wiring to keep processes efficient, accurate, and uninterrupted.

Who Needs These Food & Beverage Electrical Solutions?

Reliable electrical systems are essential across the food and beverage industry, and every person depends on them in unique ways directly or indirectly. Here’s how BTC supports each group

Food Processing and Manufacturing Companies

For companies that prepare and process food, safe and dependable electrical systems are the backbone of production. Without them, maintaining product quality and meeting hygiene standards becomes a challenge. BTC’s solutions help you to keep your production environment running smoothly while maintaining consistent product quality and meeting hygiene standards.

Beverage Manufacturers and Bottling Plants

System Integrators and Automation Contractors

Plant Owners and Operations Managers

Maintenance and Engineering Teams

Food Processing and Manufacturing Companies

For companies that prepare and process food, safe and dependable electrical systems are the backbone of production. Without them, maintaining product quality and meeting hygiene standards becomes a challenge. BTC’s solutions help you to keep your production environment running smoothly while maintaining consistent product quality and meeting hygiene standards.

Beverage Manufacturers and Bottling Plants

System Integrators and Automation Contractors

Plant Owners and Operations Managers

Maintenance and Engineering Teams

Key Features and Benefits of BTC Food & Beverage Solutions

At Bharat Trading Company (BTC), we understand that food and beverage facilities operate in tough conditions and require high-quality electrical components. That’s why our solutions are designed to support safety, hygiene, and efficiency while delivering reliable, long-lasting performance.

Built to handle moisture and washdowns

Food and beverage plants require frequent cleaning and they are frequently in contact with water and chemicals. Our BTC’s moisture-resistant insulation helps to safeguard the electrical wiring solutions during regular washdowns. This reduces the overall risk of damage and ensures smooth, uninterrupted operations.

Reliable performance in high-heat areas

Enhanced safety with fire-retardant materials

Flexible wiring for modern machinery

Clean and organised cable management

Step-by-Step: How Electrical Systems Work in Food & Beverage Plants

Power supply and distribution

Every plant starts with a steady supply of electricity. Power is brought into the facility and then distributed across different processing zones through our strong and well-insulated cables. This ensures that each section of the plant receives the right amount of power without interruptions or overloads.

Equipment and machine wiring

Automation and control systems

Monitoring and safety systems

Continuous operation and easy maintenance

Real Use Cases and Industry Examples

At Bharat Trading Company (BTC), we don’t just supply electrical components — we deliver solutions that solve real challenges for food and beverage businesses. We work closely with every food and beverage manufacturer across India and help them solve real-life operational challenges with our reliable electrical solutions. Here are a few examples of how our products have made a difference

Food Processing Plant Pune, Maharashtra

A leading food processing plant in Maharashtra was facing frequent cable damage and performance issues due to regular washdowns and long operating hours. The facility was looking for reliable electrical solutions that could withstand moisture, support heavy-duty machinery, and minimize downtime. BTC provided high-quality control cables, power cables, and moisture-resistant accessories designed specifically for food processing and packaging lines. These solutions protected all the wirings during daily cleaning cycles, supporting smooth and uninterrupted machine operation. As a result, the plant achieved improved system reliability, fewer electrical faults, and easier maintenance. The client valued BTC’s application-focused product recommendations and timely support, which helped to keep production running efficiently without interruptions.

Beverage Bottling Facility – Satara, Maharashtra

Cold Storage Facility – Gujarat

Frequently Asked Questions (People Also Ask)

Q1. What type of cables are best for food processing plants?

Q2. Why is organised cable management important in food plants?

Q3. Can standard industrial cables be used in washdown areas?

Q4. How long do food-grade electrical installations last?

Q1. What type of cables are best for food processing plants?

Q2. Why is organised cable management important in food plants?

Q3. Can standard industrial cables be used in washdown areas?

Q4. How long do food-grade electrical installations last?

Contact Bharat Trading Corporation

Need help choosing the right product or have a specific requirement? Our team is here to assist you.

BTC: Your Trusted Electrical Partner in the Food & Beverage Industry

In the food and beverage industry, every detail matters. From maintaining strict hygiene and safety standards to ensuring uninterrupted production. And, reliable electrical systems play a crucial role in keeping operations efficient, compliant, and running without downtime in this journey. At Bharat Trading Company (BTC), we understand these unique challenges. That’s why we supply high‑quality cables, accessories, and wiring solutions designed specifically for food processing plants and beverage manufacturing facilities. With our reliable products and years of industry expertise, BTC has become a trusted partner for companies across Pune, Maharashtra, and all of India. If you are looking for reliable electrical solutions for your food and beverage operations, BTC is ready to support you at every stage.